Loaded Bins Detection Using Ultrasonic Sensor

This project was really nice to work on. Beside having it implemented; having all the staff motivated to work with something new; gave good feeling. We have one machine that washes bins automatically when charged in the bin conveyor system as dirty. Those bins are supposed to be empty, since that one machine at the entrance of the bin washer would turn the bins upside down; and again at the exit another bin turner would turn the bins back to their original position. This “Turning” is required otherwise bins would get out from the bin washer full with water.

The main problem since start up; was having operators sending loaded bins as dirty.. Thus you can imagine what would happen to plates, spoons, etc.. when the bin is being turned upside down. Without forgetting the damage caused to the bin turner and the conveyors.

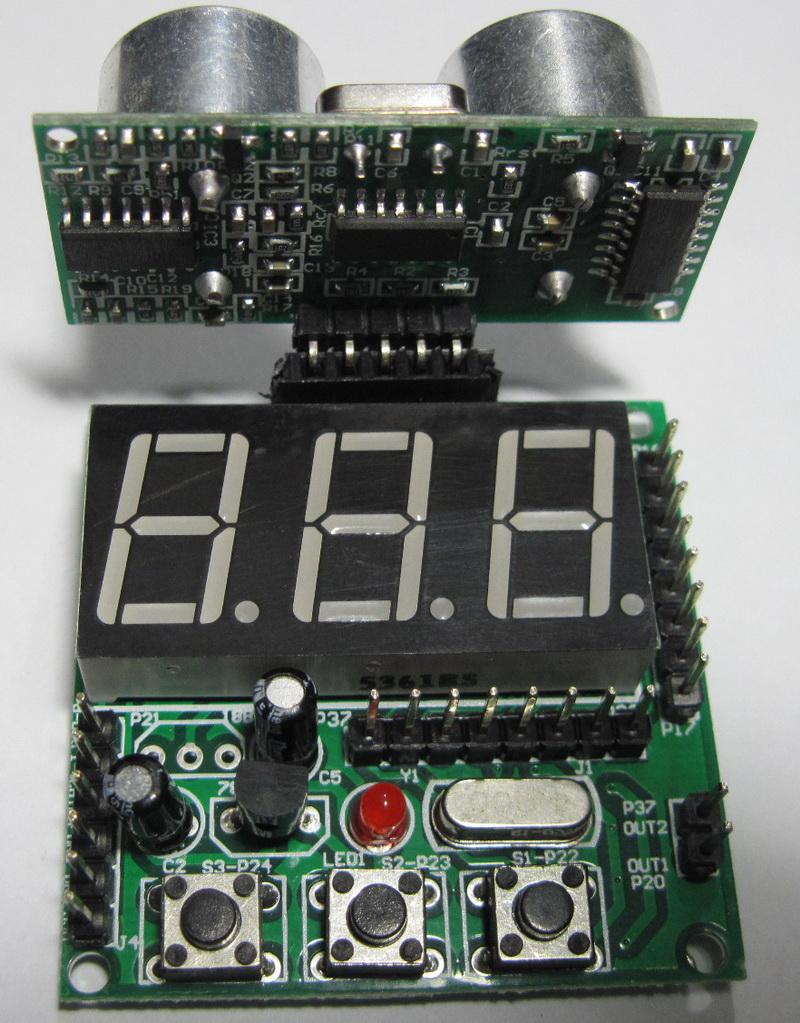

One solution that we thought about was installing an ultrasonic sensor that would detect presence of items in the bin. During one lucky night I found one ultrasonic circuit on ebay that made the entire thing possible. That circuit had a microcontroller that could be programmed to give an output when the measured distance is below a certain value. (That could be configured too.). Below a photo for this ultrasonic circuit along with its technical details:

Features:

- Ultrasonic display module use small microcomputer system controller ,use STC 10F04XE, fully compatible with 51 microcontroller

- IO port output pins, two switch output terminal, three key features, three digital display.

- With DS18B20 temperature compensation circuit Contact Interface

- Ultrasonic Ranging Module can be used directly measured the distance, you can set the distance alarm.

- The system can provide ranging program can display panel of the schematic diagram.

- Wide-voltage : DC 6~12V

- Work current : 45mA

- Range : 0 ~ 400 cm

- Maximum measurement distance : 500cm

- Test object : about the size of 6cm

- Size: 45 * 44 * 12 mm

- this module’s outputs can be user-defined

- Press and hold S1 button for 3 seconds, showing LLL

- Press the S1 key, displays a number (eg 001), Is the smallest measurement distance. When the measured distance is less than this value,OUT2 will output a high level(4.5V)

- this value can adjustable, use S2 + , use S3 –, to change.

- When setting the minimum measured value end, then click the S1 key, the display appears HHH, can set Max distance value, Press the S1 key, displays a number (eg 200), Is the max measurement distance. When measuring the distance is greater than this value, OUT1 will output a high level (4.5V). this value can adjustable, use S2 + , use S3 –, to change.

- when setting is end. press the S1 key,Save this value. With power-down memory function.

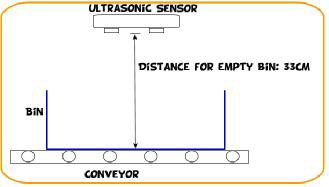

Thus the entire idea was to place the sensor above the bin at the entrance of the bin turner. Identifying the measured distance in case of empty bin would be our reference and set point for the sensor. If detected distance is less than that; that would mean presence of items inside the bin!!

The other challenge was avoiding the bins edges (for sure measured distance when the edge passes below the sensor would be less than our setpoint. For that purpose a retro reflective sensor was also installed.

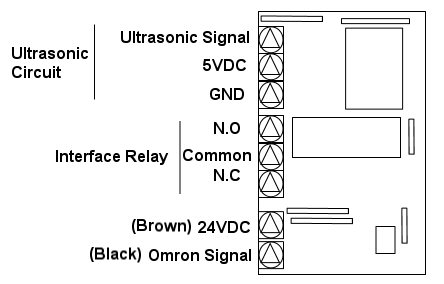

Interfacing the output coming from the sensor with the retro reflective senors along with our bin conveyor system to stop the bin in case of detecting a loaded bin; required a small interface circuit to be designed for this purpose.

When a loaded bin was detected; the N.O output was used to cause the system go into Maintenance Mode; and thus stop. That would also reflect on the monitoring system at the control room.

Currently our bin turner is safe from any intruders!! and the funniest part is when our trap stops some bins loaded with chocolate bars loaded by mistake as dirty bin.!!!

Leave a Reply